- Home /

- Capabilities /

- Metallurgy

Metallurgy

Unicast has been at the forefront of metallurgical innovation for decades. We offer multiple cutting-edge secondary materials that enhance the durability and quality of products while providing extra protection against abrasion and high-impact wear.

![]()

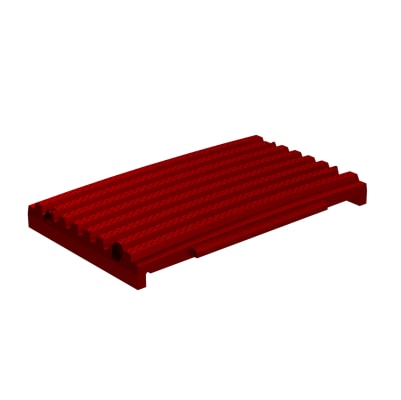

Incorporation of Titanium Carbide (TiC) inserts to the original alloys has shown to significantly increase the wear life and durability of the wear parts. Customers have reported that Unicast TiC hammers and impact bars lasted up to 7.5 longer than the original parts. It has also been reported that the TiC reinforcements resulted in up to 3.5 times increase in the wear life of the blow bars.

Unique to the North American market, Unicast’s TiC inserts are available at 20mm, 40mm, 60mm, and 80mm depths. The following wear parts are offered with TiC:

- Jaw crusher wear parts

- Horizontal shaft impactor blow pars and impactors

- Horizontal shaft impactor liners

- Hammermill hammers

- Hammermill breaker blocks

- Clinker breaker hammers

![]()

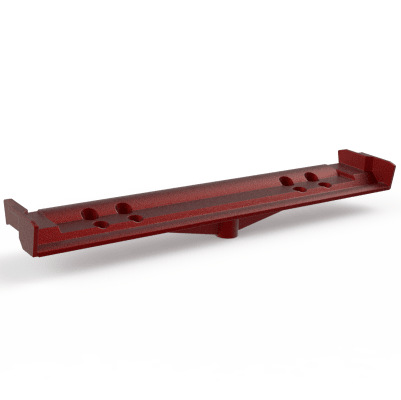

Tungsten Carbide (WC) is so hard and durable that it is used in metal machining and to cut rock in mining. Unicast’s unique tungsten carbide, branded as WOLF Technology, mixes tungsten particles into the primary casting metal to significantly increase the wear life of products.

Unicast is the only company in North America offering WOLF Technology. Currently, it is available with the following wear parts:

- Hammermill hammers

- Clinker breaker hammers

![]()

Unicast’s CRA Ceramic Reinforced Alloy products last up to 10 times longer than their traditional alloy counterparts. Cast in one piece for maximum durability, ceramic liners create an internal shield for products and protect wear parts from high abrasion. Wear parts incorporating CRA (Ceramic Reinforced Alloy) offer considerable advantages over regular ferrous alloys with respect to abrasion resistance and toughness. We have also used CRA reinforcements in our high chrome iron alloys. Unicast manufactures a range of Metal Matrix Composite (Alloy + Ceramic) wear parts with excellent properties in extremely abrasive conditions.

The following products are offered with CRA Ceramic Reinforced Alloy:

- Horizontal shaft impactor blow pars and impactors

- Hammermill hammers

- Roller mill wear parts (bases, tables, roller tire segments)

- Clinker breaker hammers

Looking for specifications? Click for information about our typical alloys